Introduction: Why Cold Room Systems Matter

A cold room system is the backbone of modern cold-chain infrastructure. From food preservation and pharmaceutical storage to logistics hubs and industrial processing, cold room systems ensure products remain within precise temperature ranges to protect quality, safety, and regulatory compliance. As global demand for fresh food, vaccines, and temperature-sensitive goods increases, businesses require reliable, energy-efficient, and scalable cold storage solutions.

Unlike standalone refrigeration equipment, a cold room system is a fully integrated solution—combining insulated structures, refrigeration technology, access control, flooring, and monitoring into a single engineered environment. This guide provides a deep, end-to-end overview of cold room systems, covering components, design principles, performance optimization, applications, and buying considerations—serving both informational and transactional search intent.

What Is a Cold Room System?

A cold room system is a purpose-built, temperature-controlled enclosure designed to store, process, or stage products at low temperatures for extended periods. It is engineered as a system rather than a single product, ensuring compatibility, efficiency, and reliability across all components.

Cold room systems are commonly designed for:

- Chiller rooms: 0 °C to +5 °C

- Freezer rooms: −18 °C

- Deep freezers: −25 °C to −40 °C

- Blast freezing systems: Rapid temperature pull-down for food processing

By integrating insulation, refrigeration, doors, floors, and controls, cold room systems minimize thermal losses, stabilize temperatures, and reduce operating costs across the product lifecycle.

Core Components of a Cold Room System

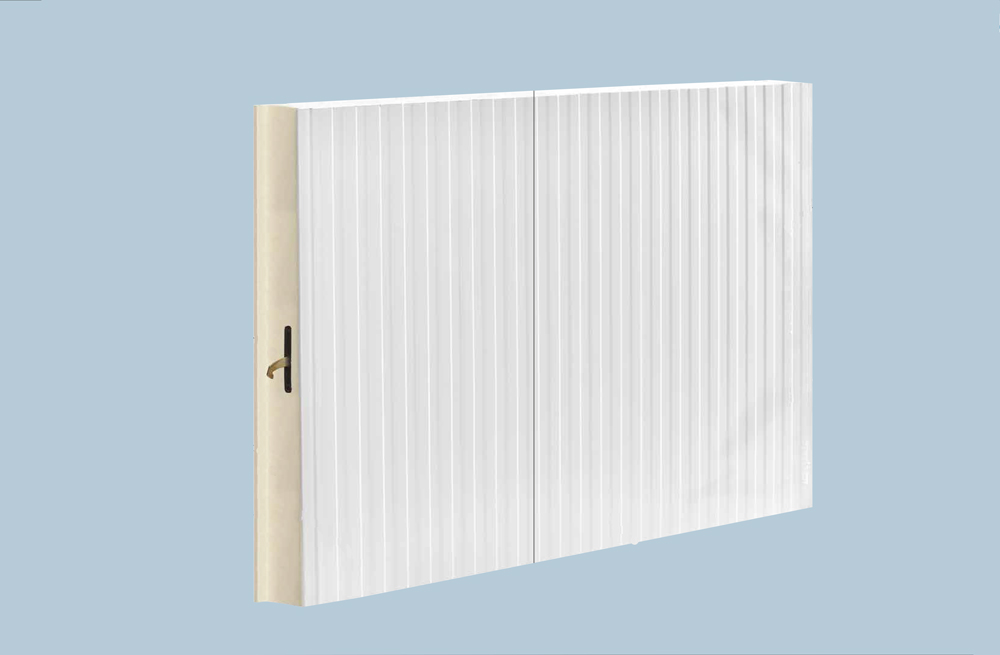

1. Insulated Cold Room Panels

Insulated panels form the envelope of the cold room. High-performance systems use PU (polyurethane) or PIR (polyisocyanurate) foam cores due to their low thermal conductivity and excellent structural integrity.

Key characteristics:

- Thickness options: 75 mm, 100 mm, 120 mm, 150 mm

- Foam density: 40–45 kg/m³

- Surface finishes: color-coated steel, stainless steel, embossed aluminum

- Connection: cam-lock tongue-and-groove system for airtight joints

Well-designed panels significantly reduce heat transfer, directly impacting energy consumption and long-term operating costs.

2. Refrigeration System (Cooling Unit)

The refrigeration system is the heart of the cold room. It removes heat from the room and maintains the target temperature. A complete refrigeration setup typically includes:

- Compressor (semi-hermetic or scroll)

- Condenser (air-cooled or water-cooled)

- Evaporator

- Expansion valve

- Refrigerant piping and controls

System sizing is calculated based on room volume, target temperature, product load, ambient temperature, door-opening frequency, and operating hours. Proper matching prevents short cycling, reduces wear, and ensures consistent temperature control.

3. Cold Room Doors

Doors are a critical interface between the cold environment and ambient air. Poorly designed doors can cause significant energy loss.

Common door types:

- Hinged doors (personnel access)

- Sliding doors (forklift and pallet access)

- Semi-flush or flush-mounted freezer doors

For freezer applications, doors are equipped with frame heaters and anti-condensation features to prevent ice buildup and ensure smooth operation.

4. Flooring and Subfloor Insulation

Cold room flooring must support loads, prevent moisture ingress, and block ground heat. A typical cold room floor system includes:

- XPS insulation boards

- Vapor barrier

- Reinforced concrete

- Anti-slip aluminum checker plates or epoxy finish

For freezer rooms, proper subfloor insulation is essential to prevent frost heave, which can damage foundations and compromise safety.

5. Control and Monitoring Systems

Modern cold room systems rely on precise controls to ensure safety and efficiency:

- Digital temperature controllers

- High/low temperature alarms

- Defrost timers

- Optional remote monitoring and data logging

Advanced systems integrate cloud-based monitoring, enabling real-time alerts, compliance reporting, and predictive maintenance—especially critical in pharmaceutical and food sectors.

How Cold Room Systems Are Designed

Load Calculation and Engineering

Design begins with a detailed thermal load calculation, accounting for:

- Transmission load (heat through walls, ceiling, floor)

- Product load (incoming warm goods)

- Infiltration load (door openings)

- Equipment and personnel load

- Lighting and defrost load

Accurate calculations ensure the refrigeration system is neither undersized (risking temperature instability) nor oversized (wasting energy).

Panel Thickness and Insulation Selection

Panel thickness is selected based on target temperature and ambient conditions:

- 75 mm for coolers and mild climates

- 100 mm for standard freezers

- 120–150 mm for deep-freeze or hot climates

PIR panels are often chosen for higher fire resistance and improved thermal stability.

Energy Efficiency Considerations

Energy efficiency is a key buying driver. High-performance cold room systems feature:

- Low thermal conductivity insulation

- High-efficiency compressors

- Optimized evaporator airflow

- Tight sealing and minimized thermal bridges

- Smart defrost and control strategies

These features can reduce operating costs by 20–40% over the system’s lifetime.

Applications of Cold Room Systems

Food and Beverage Industry

Cold room systems preserve freshness, slow bacterial growth, and extend shelf life for:

- Meat and poultry

- Seafood

- Dairy products

- Fruits and vegetables

- Beverages and ready-to-eat foods

Pharmaceutical and Healthcare Storage

Vaccines, medicines, and biological samples require strict temperature control and monitoring. Cold room systems support compliance with GMP and cold-chain regulations.

Logistics and Cold Chain Warehousing

Large-scale cold storage facilities rely on modular cold room systems for staging, consolidation, and distribution—forming a critical link in the global cold chain.

Hospitality and Retail

Hotels, restaurants, and supermarkets use cold room systems for back-of-house storage, ensuring food safety while optimizing space and energy use.

Modular vs. Traditional Cold Room Systems

Modular Cold Room Systems

- Factory-engineered components

- Fast installation and commissioning

- Flexible sizing and relocation

- Consistent quality and performance

Traditional Built-in Cold Rooms

- Longer construction timelines

- Higher labor costs

- Limited flexibility for expansion

For most modern applications, modular cold room systems offer superior ROI, scalability, and speed to market.

Installation Process Overview

- Site preparation and leveling

- Subfloor insulation and vapor barrier

- Wall panel installation with cam-locks

- Ceiling panel installation and supports

- Door installation and sealing

- Refrigeration unit installation

- Electrical wiring and controls

- Commissioning and temperature testing

Professional installation ensures airtightness, safety, and long-term performance.

Maintenance and Lifecycle Management

A cold room system is a long-term asset. Proper maintenance includes:

- Regular inspection of door seals

- Cleaning evaporator coils

- Monitoring refrigerant pressures

- Verifying temperature sensors and alarms

Preventive maintenance reduces downtime, extends equipment life, and protects stored goods.

How to Choose the Right Cold Room System (Buyer’s Guide)

When sourcing a cold room system, evaluate:

- Required temperature range and stability

- Storage volume and turnover rate

- Ambient climate conditions

- Energy efficiency targets

- Compliance requirements

- Supplier experience and after-sales support

A well-selected system balances initial investment with long-term operating costs.

Cold Room System as a Strategic Investment

A cold room system is more than storage—it is a strategic infrastructure investment. High-quality systems reduce spoilage, ensure compliance, lower energy bills, and support business growth. Whether for food, pharmaceuticals, or logistics, choosing the right cold room system delivers measurable value across the entire cold chain.

Conclusion

The modern cold room system is a sophisticated, modular, and energy-efficient solution designed to meet the demands of today’s temperature-controlled industries. By integrating insulation, refrigeration, access, flooring, and intelligent controls, cold room systems provide reliable performance and long-term cost efficiency. For businesses seeking dependable cold storage, a professionally designed cold room system is the foundation of success.