Installing a cold room requires precision, expertise, and attention to countless details. Whether you’re a facility manager planning your first cold storage project or a contractor looking to improve your installation quality, this comprehensive guide covers everything you need to know about proper cold room installation and how to assess the results.

A well-executed cold room installation can serve your business for decades, maintaining optimal temperatures while keeping energy costs low. However, poor installation practices can lead to temperature fluctuations, excessive energy consumption, and costly repairs. Let’s explore the critical considerations that separate professional installations from problematic ones.

Key Points to Consider When Installing a Cold Room

Site Selection and Foundation

The foundation of any successful cold room installation begins literally with the foundation itself. Your chosen site must feature flat, solid ground capable of supporting both the cold room structure and the substantial weight of stored goods.

Environmental factors play a crucial role in site selection. Avoid locations exposed to high temperatures, excessive humidity, or constant vibration from nearby equipment. These conditions force your refrigeration system to work harder, increasing energy costs and reducing equipment lifespan.

Proper drainage cannot be overlooked. Water accumulation around your cold room creates multiple problems, from structural damage to ice formation that can compromise the building’s integrity. Ensure your site includes adequate drainage systems or the ability to install them during construction.

Insulation Materials and Installation

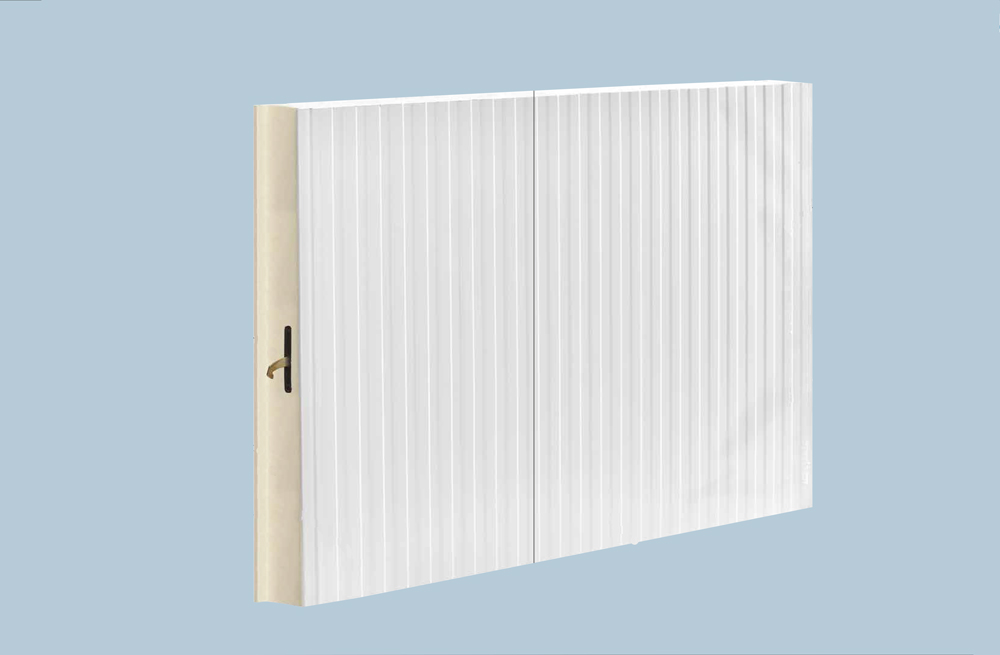

Selecting appropriate thermal insulation materials directly impacts your cold room’s efficiency and operating costs. The thickness requirements vary significantly based on your temperature needs. Chiller applications typically require 100mm panels, while freezer installations demand 150–200mm thickness for optimal performance.

Common panel materials include polyurethane (PU), polyisocyanurate (PIR), and expanded polystyrene (EPS). Each offers different benefits in terms of insulation value, fire resistance, and cost. Your contractor should recommend materials based on your specific temperature requirements and budget constraints.

Installation quality matters as much as material selection. All panel joints require proper sealing with high-grade silicone to prevent thermal bridges and air leakage. Even small gaps can dramatically impact efficiency and create moisture problems. Panels must align perfectly flat, and cam-locks need secure fastening to maintain structural integrity over time.

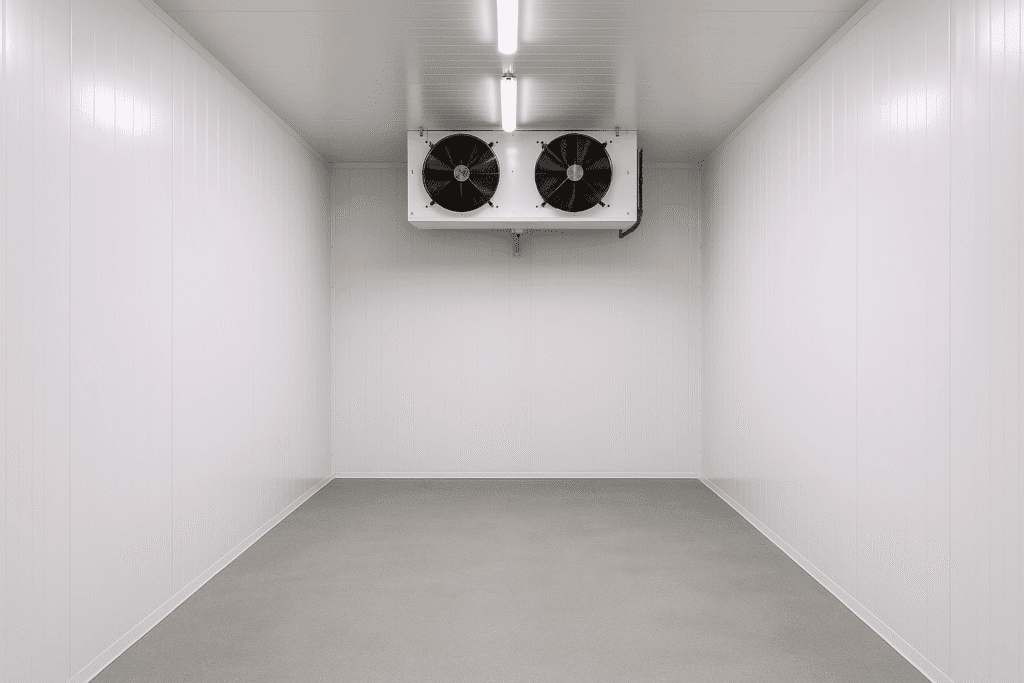

Refrigeration System Installation

The refrigeration unit represents the heart of your cold room system, making proper installation critical for reliable operation. Position the unit in a well-ventilated area with easy access for maintenance and repairs. Poor ventilation forces the system to work harder, while difficult access increases service costs.

Pipeline installation requires professional welding techniques to prevent refrigerant leaks. High-quality installations use nitrogen protection during welding to prevent oxidation and contamination. Any leaks in the refrigerant lines reduce efficiency and can cause complete system failure.

All refrigeration pipelines need proper insulation to prevent condensation and energy loss. Uninsulated lines create moisture problems and force the system to work harder to maintain temperature. Additionally, electrical wiring must comply with local electrical safety standards, with control boxes featuring appropriate overload protection to prevent equipment damage.

Cold Room Door Installation

Door installation presents unique challenges, particularly for freezer applications. Anti-condensation heating wires around the door frame prevent ice formation that can make doors impossible to open. This feature is essential for freezer installations but beneficial for all cold rooms in humid environments.

The door itself must provide excellent sealing while remaining easy to operate. Poor door sealing wastes energy and creates temperature fluctuations that can damage stored products. However, doors that are too tight or poorly balanced become difficult to use, creating operational problems for staff.

Ventilation and Drainage

Interior drainage systems require careful planning and execution. The floor must include proper slope to ensure condensate water flows to drain points without pooling. Standing water inside cold rooms creates slip hazards and can freeze, causing damage to floor surfaces.

Pressure relief valves help prevent negative pressure situations that make doors difficult to open. When warm air enters a cold room and rapidly cools, it creates vacuum conditions that can trap people inside or damage the structure. Proper ventilation systems address these safety concerns while maintaining temperature control.

Commissioning and Testing

The commissioning phase separates professional installations from amateur work. Proper commissioning includes comprehensive pressure testing to identify any leaks in the refrigeration system. This testing must occur before adding refrigerant to ensure system integrity.

Vacuuming the system removes moisture and air that can damage equipment and reduce efficiency. The process requires specialized equipment and knowledge of proper procedures. Refrigerant charging must follow manufacturer specifications exactly, as both undercharging and overcharging create performance problems.

During initial operation, monitor cooling speed and overall system efficiency. A properly installed system should reach target temperatures within specified timeframes while maintaining consistent performance.

How to Judge the Quality of a Cold Room Installation

Appearance and Details

Visual inspection reveals much about installation quality. Well-assembled panels feature smooth joints with no visible gaps or misalignment. Professional installations show attention to detail in every connection and finishing touch.

Examine sealant application carefully. Even application with no light leakage through joints indicates proper installation techniques. Uneven or missing sealant suggests rushed work that will cause problems later.

Test the cold room door operation thoroughly. Quality installations feature doors that seal properly while opening and closing smoothly. Difficult operation or poor sealing indicates installation problems that need immediate attention.

Operational Performance

Temperature performance provides the ultimate test of installation quality. Your cold room should reach set temperatures within specified timeframes and maintain consistent temperatures throughout the space. Hot or cold spots indicate poor air circulation or insulation problems.

Listen to the refrigeration equipment during operation. Smooth, quiet operation suggests proper installation and setup. Unusual noises, excessive vibration, or erratic cycling patterns indicate installation problems that require professional attention.

Monitor temperature consistency over several days of operation. Quality installations maintain stable temperatures with minimal fluctuation, while poor installations show wide temperature swings that waste energy and potentially damage stored products.

Energy Consumption and Stability

Analyze compressor cycling patterns to assess system health. Properly sized and installed systems cycle on and off at reasonable intervals without short cycling or continuous operation. Frequent cycling suggests installation problems or inadequate system sizing.

Track power consumption compared to manufacturer specifications and industry benchmarks. Excessive energy use often indicates installation problems such as refrigerant leaks, poor insulation, or inadequate system setup.

Examine the condenser for proper heat dissipation. Normal operation shows appropriate temperature differences between inlet and outlet air. Frost or ice formation on refrigeration lines indicates installation problems that require immediate attention.

User Experience

Daily operation reveals installation quality through user experience. Doors should open easily without excessive ice formation around seals. Severe icing indicates installation problems with door seals or heating elements.

Interior lighting and safety features should function properly and remain accessible for maintenance. Quality installations include all necessary safety equipment installed according to code requirements.

Long-term performance provides the final assessment of installation quality. Well-installed cold rooms maintain performance for years without panel condensation, structural settling, or deformation. Problems in these areas indicate installation shortcuts that create ongoing maintenance issues.

Ensuring Long-Term Success

A well-installed cold room represents a significant investment in your business’s future. Quality installation provides years of reliable service while minimizing energy costs and maintenance requirements. The key lies in working with experienced professionals who understand the complexity of modern refrigeration systems and the importance of proper installation techniques.

Remember that the cheapest installation often becomes the most expensive over time. Poor installation creates ongoing problems that increase operating costs and reduce system lifespan. Invest in quality installation from the beginning to ensure your cold room serves your business effectively for decades to come.

By following these guidelines and working with qualified professionals, you can achieve a cold room installation that meets your needs while providing reliable, efficient operation for years to come.